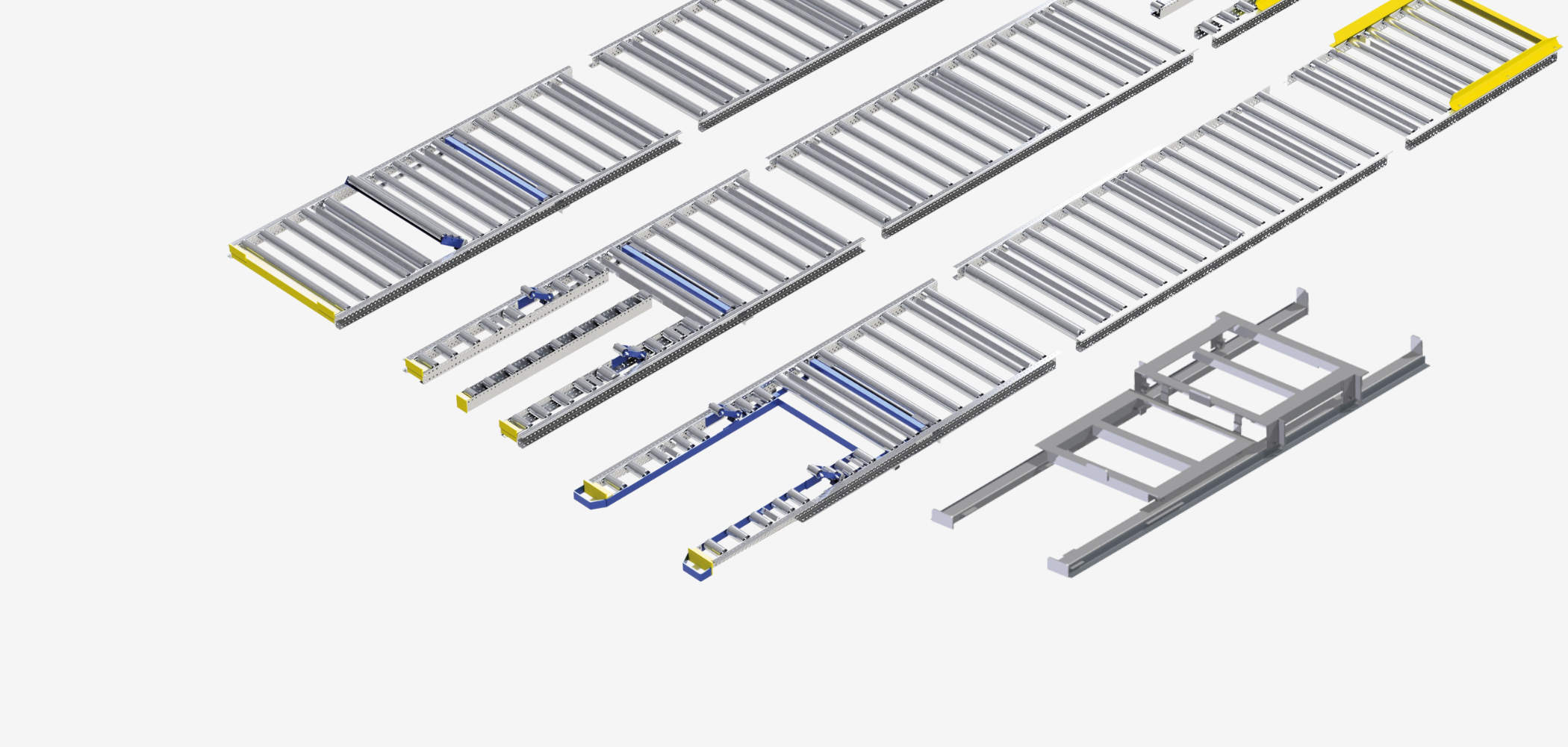

Paletten-Durchlauf- und

Wirtschaftliche schwerkraftbetriebene Lösungen für optimalen Materialfluss.

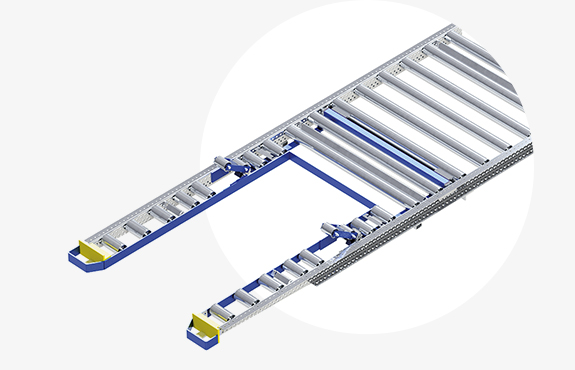

Wir stellen schwerkraftbetriebene Lager- und Fördertechnik her. In den Systemen von euroroll kommen ausschließlich schwerkraftbetriebene Rollensysteme zum Einsatz. Damit entfallen aufwendige elektrische Verkabelungen und zusätzliche Stromkosten.

Rollenbahnen lassen sich auf mehreren Ebenen über- und nebeneinander in ein Regalsystem einbauen. Die Höhe und Tiefe werden auf Ihren Platzbedarf angepasst.

Wir arbeiten mit einem modularem Prinzip. Jede Rollenbahn besteht aus mindestens einem Aufgabe-, Mittel- und Entnahmeelement. Denkbar einfach und robust auf höchstem technischen Niveau.

Vorteile

Wirtschaftlicher Arbeiten durch optimale Flächenausnutzung im Lager

✓ Unsere Rollenbahnen für Paletten sind ausgesprochen robust und für den Dauereinsatz ausgelegt. Sollten trotzdem einmal Defekte auftreten, lassen sie sich durch das Austauschen von Einzelteilen schnell beheben.

✓ Paletten-Durchlauf-Systeme von Euroroll eignen sich sowohl für Palettenlager nach dem FIFO-Prinzip (First In, First Out) als auch nach dem LIFO-Prinzip (Last In, First Out), für Pufferlager, aber auch für Sonderlösungen, die exakt auf die Bedürfnisse in Ihrem Lager abgestimmt sind.

✓ Paletten-Durchlauf-Systeme benötigen bis zu 50% weniger Platz als herkömmliche Palettenlager. Die Gänge zwischen den einzelnen Regalreihen entfallen, der vorhandene Lagerraum kann besser ausgenutzt werden.

✓ Die Energiekosten sinken. Die Paletten bewegen sich auf Rollenbahnen mit leichtem Gefälle ausschließlich mithilfe der Schwerkraft fort. Eine zusätzliche Energiezufuhr ist nicht erforderlich. Da sich zudem die Wege für die Bediengeräte verkürzen, fallen oft auch deren Energiekosten.

Module

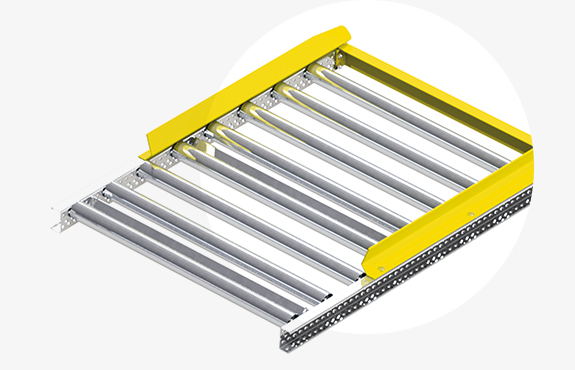

Aufgabe-Elemente

Durchgehende Rollen

Für Bediengeräte mit neigbarem Mast und die automatische Bestückung.

Mit Einsetztrichter zur sicheren Aufgabe für die Gabelstablerfahrer, mit gelber Signalfarbe markiert. Mit Rollenschutz, damit im täglichen Gebrauch die Rollen nicht beschädigt werden. Bei der automatischen Aufgabe wird das Aufgabe-Element mit einer verstärkten ersten Rolle ausgeliefert.

Geteilte Rolle

Für Bediengeräte ohne Mastneigung.

Optional mit zwei oder drei voneinander getrennten Rollensträngen.

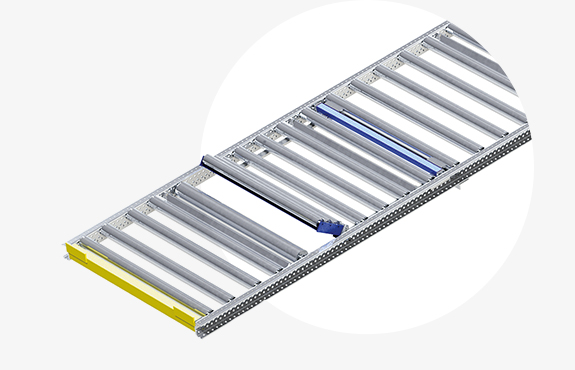

Mittel-Element

Durchgehende Rollen

Unabhängig vom Bediengeräte.

Auf jedem Mittel-Element finden zwei Paletten Platz. Die Anzahl der aneinandergereihten Mittel-Elemente bestimmen die Tiefe der Rollenbahn.

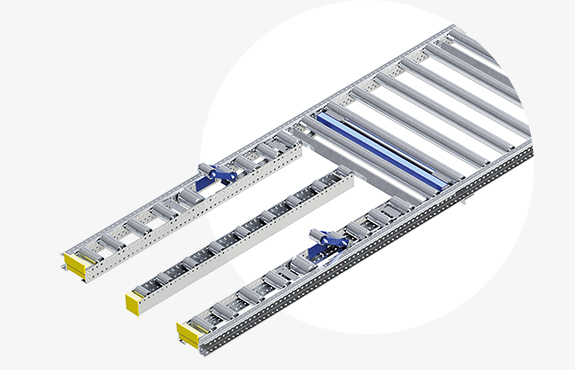

Entnahme-Elemente

Durchgehende Rollen

Für Bediengeräte mit neigbarem Mast.

Die Trennvorrichtung separiert die zu entnehmende Palette von den nachfolgenden. Mit Endanschlag zum Schutz der Rollen im täglichen Gebrauch, mit gelber Signalfarbe markiert.

Geteilte Rolle

Für Bediengeräte ohne Mastneigung.

Je nach Palettenart ist das Entnahme-Element zwei- oder dreigeteilt. Die Trennvorrichtung separiert die zu entnehmende Palette von den nachfolgenden. Mit Endanschlag zum Schutz der Rollen im täglichen Gebrauch, mit gelber Signalfarbe markiert.

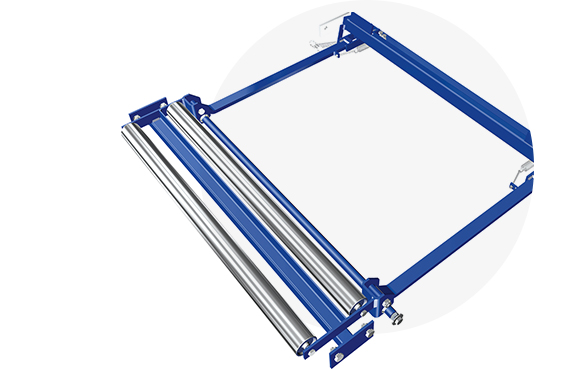

Boden-Element

Wahlweise mit zusätzlichen Verstärkungen.

Optional mit zusätzlichen Verstärkungen, um Beschädigungen an der Rollenbahn zu vermeiden.

Cart Push-Back

Cart System als Alternative zum Einschubsystem

mit Rollen

Für den optimierten Quertransport mit LIFO-Prinzip

Effizientes Handling, optimierte Sicherheit und keinerlei Energieverbrauch. Die Euroroll Cart Push-Back Systeme für die Einlagerung von bis zu 6 Paletten in der Tiefe. Mit allen Regalen kompatibel und für fast alle Palettentypen und Stahlgestelle einsetzbar. Mit bis zu 1.300kg Belastung pro Palettenplatz bieten die Cart Systeme eine hohe Lagerkapazität und bis zu 30% Platzersparnis im Vergleich zu konventionellen Regalen.

✓ Für die Lagerung von fast allen Palettentypen geeignet. Ob Europalette, CHEP Palette, GMA und viele weitere asiatische und australische Paletten.

✓ Kein Staudruck bei der Entnahme, da sich die Paletten bei der Einlagerung nicht berühren.

✓ Vormontierte Lieferung der Einschubwagen und einfache Installation in bereits vorhandene Drive-in Regale.

✓ Robuste, pulverbeschichtete Schienen und Einschubwagen, für den rauen Arbeitsalltag im Lager.

Zubehör

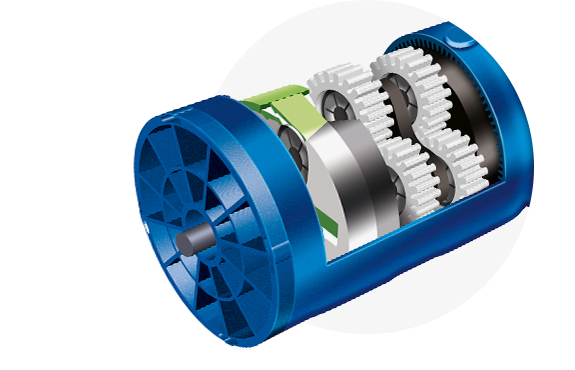

Bremsrolle

Gummiert, Gerändelt und Standard. Bremstragrollen für jeden Bedarf. Wir beraten Sie welche Bremstragrolle optimal für Ihre Bedürfnisse ist.

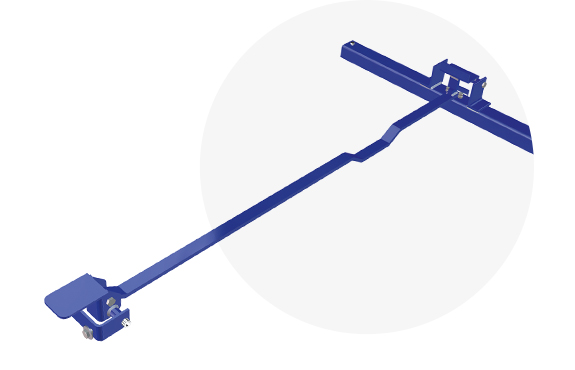

Trennvorrichtungen

Für eine schnelle und sichere Entnahme. Die Trennvorrichtung separiert auf der Entnahmeseite die zu entnehmende Palette von den nachfolgenden Paletten.

Zubehör

Wichtiges Zubehör für Ihr System. Wir beraten Sie, individuell auf für Ihre Bedürfnisse abgestimmt.

Neue Studie: Pallet Flow vs. Pallet Shuttle

Effiziente Lösungen für die Lagerung von Paletten mit hoher Dichte

Das Fraunhofer Institut hat in Zusammenarbeit mit Euroroll ein Whitepaper veröffentlicht, welches die beiden Regalsysteme Pallet Flow und Pallet Shuttle vergleicht und die Vor- und Nachteile beider Systeme beleuchtet. Die Ergebnisse können Sie sich in dem kostenlosen Whitepaper ansehen.