euroroll ist stolz, einige der früheren Projekte vorzustellen, die nach Kundenwunsch entworfen und gebaut wurden. Besonders hervorzuheben sind die einzigartigen Lösungen, die für jeden Kunden entwickelt wurden. euroroll garantiert jedem Kunden die bestmögliche Lösung und setzt dabei nicht nur auf das Standardsortiment, sondern auch auf Sonderlösungen und Sonderanfertigungen nach Kundenwunsch.

Automobil

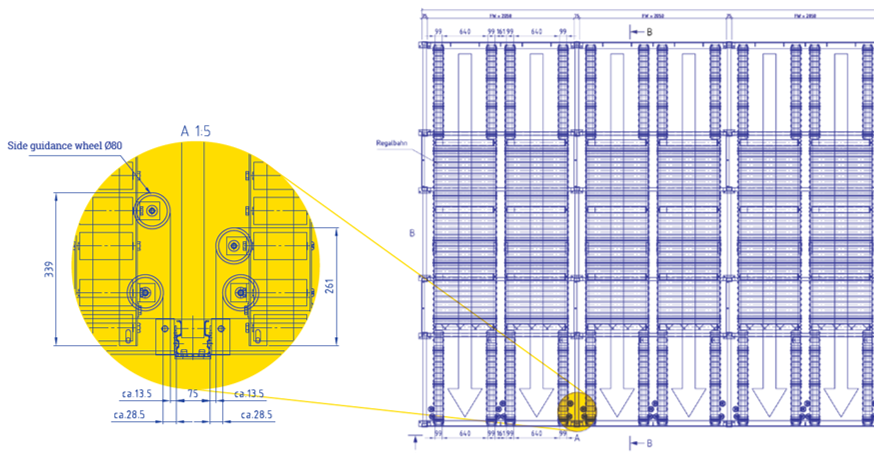

Für dieses Unternehmen der Automobilindustrie wurde ein komplett neues Motorenwerk mit modernsten Lagereinrichtungen und mehrere Blöcke mit Durchlaufregalen bereitgestellt. Für die typischen Industrie-Automobilcontainer und Stahlrahmen wurde eine Sonderlösung entwickelt, die ein Seitenprofil mit integrierter Seitenführung beinhaltet. Zusätzlich hält der Doppelvereinzeler mit extra hohem Halteanschlag die erste Palette frei von jeglichem Liniendruck der nachfolgenden Paletten.

Handel

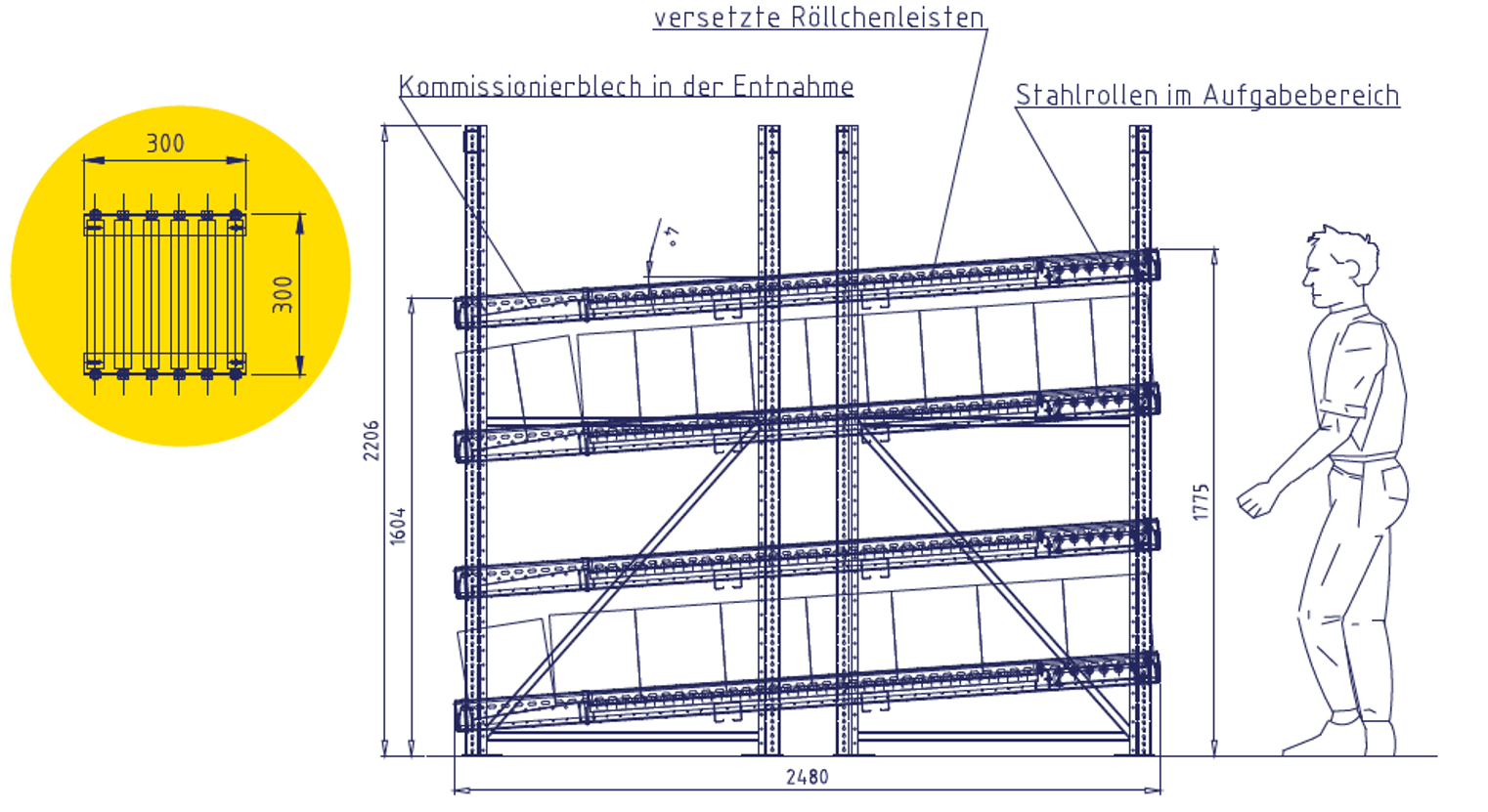

Mit der versetzten Anordnung der Radschienen hat Euroroll eine Lösung gefunden, um Kisten mit unterschiedlichen unregelmäßigen Wabenstrukturen zuverlässig zum Kommissionierplatz zu transportieren. Auf der Abladeseite bremst ein gekipptes Kommissioniertablett die Kisten ab und präsentiert diese ergonomisch so, dass sie bequem entnommen werden können. Die nach dem FIFO-Prinzip arbeitenden Profile des Carton Flow bestehen aus verzinktem Stahl und bilden eine äußerst robuste Konstruktion.

Konsumgüter

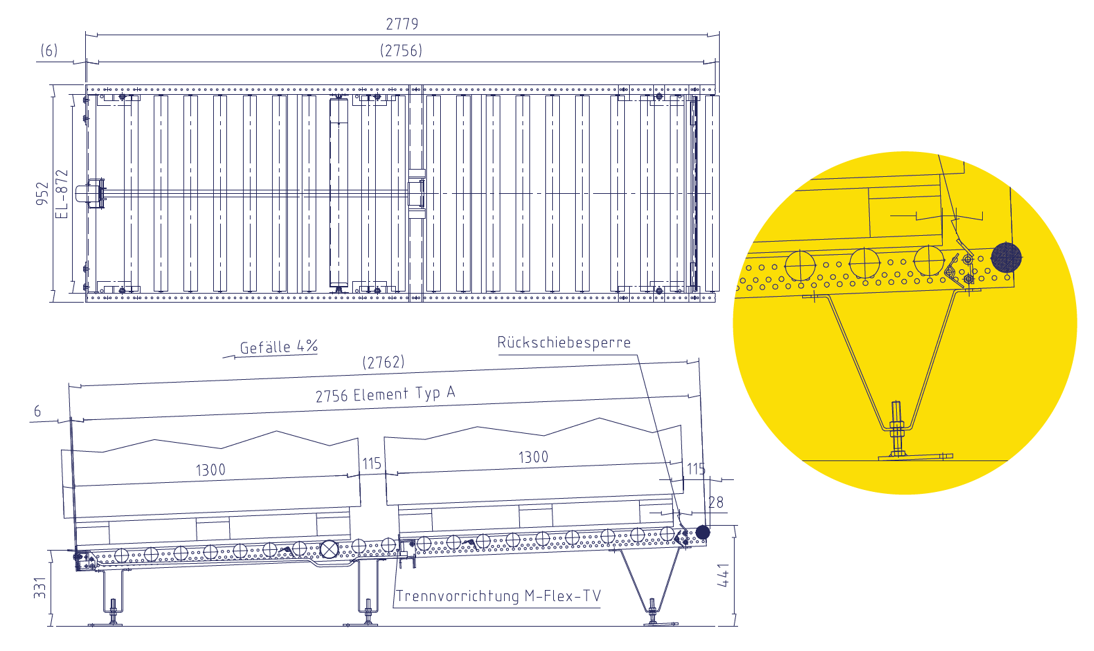

Für einen der größten deutschen Süßwarenkonzerne hat Euroroll eine teilautomatisierte Lagerlösung konzipiert: eine Kombination aus Schwerkraftrollenbahnen, angetriebenen Rollen und automatisierter Beschickung per Verschiebewagen. Die langen, schwerkraftbetriebenen Gassen sind als Zwischenspeicher (Pufferlösung) gedacht.

Der Shuttlewagen belädt sie automatisch mit Paletten. Am Ende der Bahn ist eine Vereinzelungsvorrichtung installiert, damit der Bediener eine Palette ohne Liniendruck entnehmen kann. Die Gleise sind für den Betrieb mit Handhubwagen geeignet. Der Gewichtsbereich der Paletten kann zwischen 80 und 1000 kg variieren. Ein Transferwagen befüllt automatisch die Kommissioniergassen.

Logistik

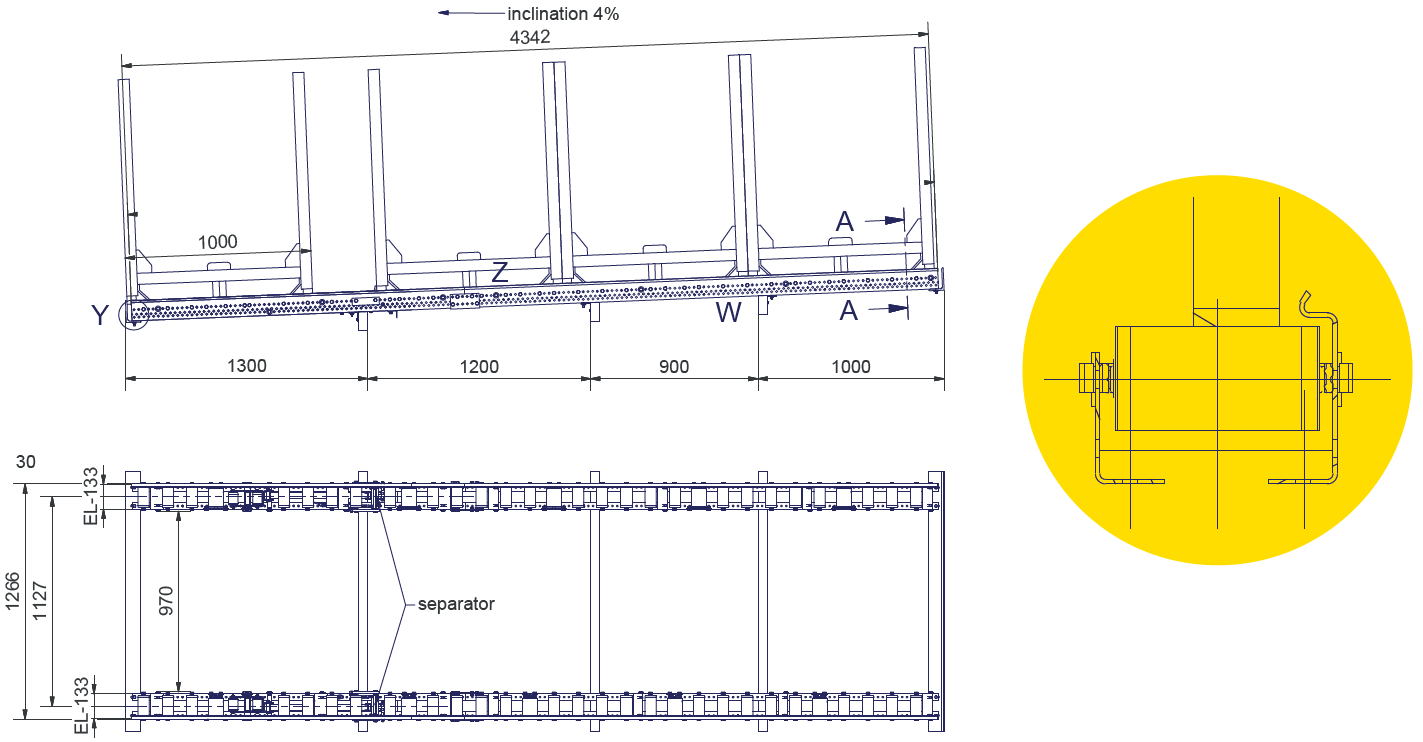

Für dieses Unternehmen in der Elektroindustrie konnte Euroroll Schwerkraftrollenbahnen auch mit AGV’s einsetzen. Das Be- und Entladen der Paletten erfolgt automatisiert. Dieses System kann nicht nur mit Standard-Europaletten, sondern auch mit Sonderpaletten, Stahlgestellen und Kunststoffpaletten beladen werden. Die Konfiguration der Rollenbahnen erfolgte in enger Zusammenarbeit mit dem FTS-Hersteller, um einen reibungslosen und zuverlässigen Betrieb zu gewährleisten. Auch die Integration einer Sprinkleranlage und einer Volleinhausung mit Brandschutzverkleidung wurde integriert.

Pharma

Zwei Systeme – zusammen und nicht gegeneinander!

Für dieses Unternehmen der Pharmaindustrie werden die Vorteile zweier Systeme genutzt. Die Kombination aus Schwerkraft-Rollenbahnen im Erdgeschoss und einem Funk-Shuttle in den höheren Ebenen trägt zu einer optimalen Kommissionierung bei. Die beiden Systeme ergänzen sich perfekt und werden von der Euroroll Bremsrolle Typ EBT2S unterstützt, die den Quertransport der Paletten schonend steuert und die maximale Abwurfgeschwindigkeit von 0,25 m/s einhält. Darüber hinaus ermöglicht die speziell für den Quertransport modifizierte Vereinzelungsvorrichtung „Flex TV“ das Entladen der ersten Palette ohne Liniendruck und sorgt für eine schnelle und sichere Kommissionierung. Bei der verwendeten Lösung kann das Entladeelement der Rollenbahn mittels einer Gasdruckstrebe angehoben werden. Dies erleichtert die Reinigung des darunter liegenden Bodens.