Pallet Flow Racking offers economical gravity flow solutions for optimized product handling. We are the leading manufacturer of gravity-driven storage and conveyor technology. Only gravity-driven rollers are used in Euroroll’s systems, eliminating the need for complex electrical cabling and additional electricity costs.

Contact us to get economical gravity flow solutions for optimized product handling.

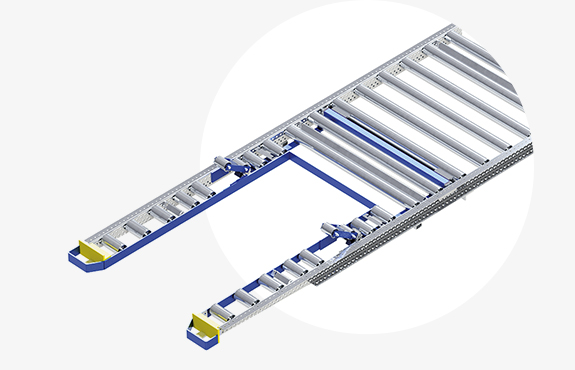

Roller conveyors can be installed on multiple levels, both above and adjacent to each other, in a racking system. The height and depth are customized to fit your specific space requirements.

Operating on a modular principle, each roller conveyor in our Pallet Flow Racking system consists of at least one loading, center, and unloading element. Our systems are reliable, efficient, and engineered to the highest technical standards.

Unlock the Full Potential of Your Warehouse with Pallet Flow Racking Advantages

More economical work through optimal use of space in the warehouse

✓ Pallet flow rack systems require up to 50% less space than conventional pallet warehouses. The aisles between the individual rows of shelves are omitted, and the existing storage space can be better used. Safe space!

✓ Increased productivity. As the travel distances for your operators become shorter, it is possible to handle larger quantities of goods in the same amount of time. Euroroll gravity conveyors are extremely robust and designed for continuous use. Should defects nevertheless occur, they can be remedied quickly (usually during operation) by replacing individual parts.

✓ Energy costs are reduced. The pallets move on roller conveyors with a slight slope exclusively with the help of gravity. An additional energy supply is not required. Since the travel distances for the material handling equipment is reduced with gravity conveyors, also this energy is saved. Safe energy!

✓ Pallet Flow Racking Gravity Systems from Euroroll are suitable for warehouses according to the FIFO principle (First In, First Out) as well as the LIFO principle (Last In, First Out), for Buffer storages, but also for special applications that are tailor-made for the customers needs.

Explore the Modular Flexibility of Euroroll Pallet Flow Racking Systems

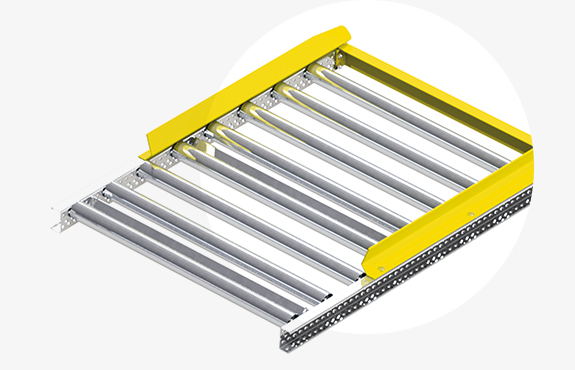

Loading Element

Full-Width Rollers

For material handling equipment with tilting mast and automated loading of the conveyors.

With entry guides for safe positioning for the forklift drivers, marked with a yellow signal color. With roller protection, so that the rollers are not damaged in daily use. In automated systems, a reinforced roller will be fitted.

Split Rollers

For material handling equipment without mast inclination.

Optionally, with two or three separate roller tracks.

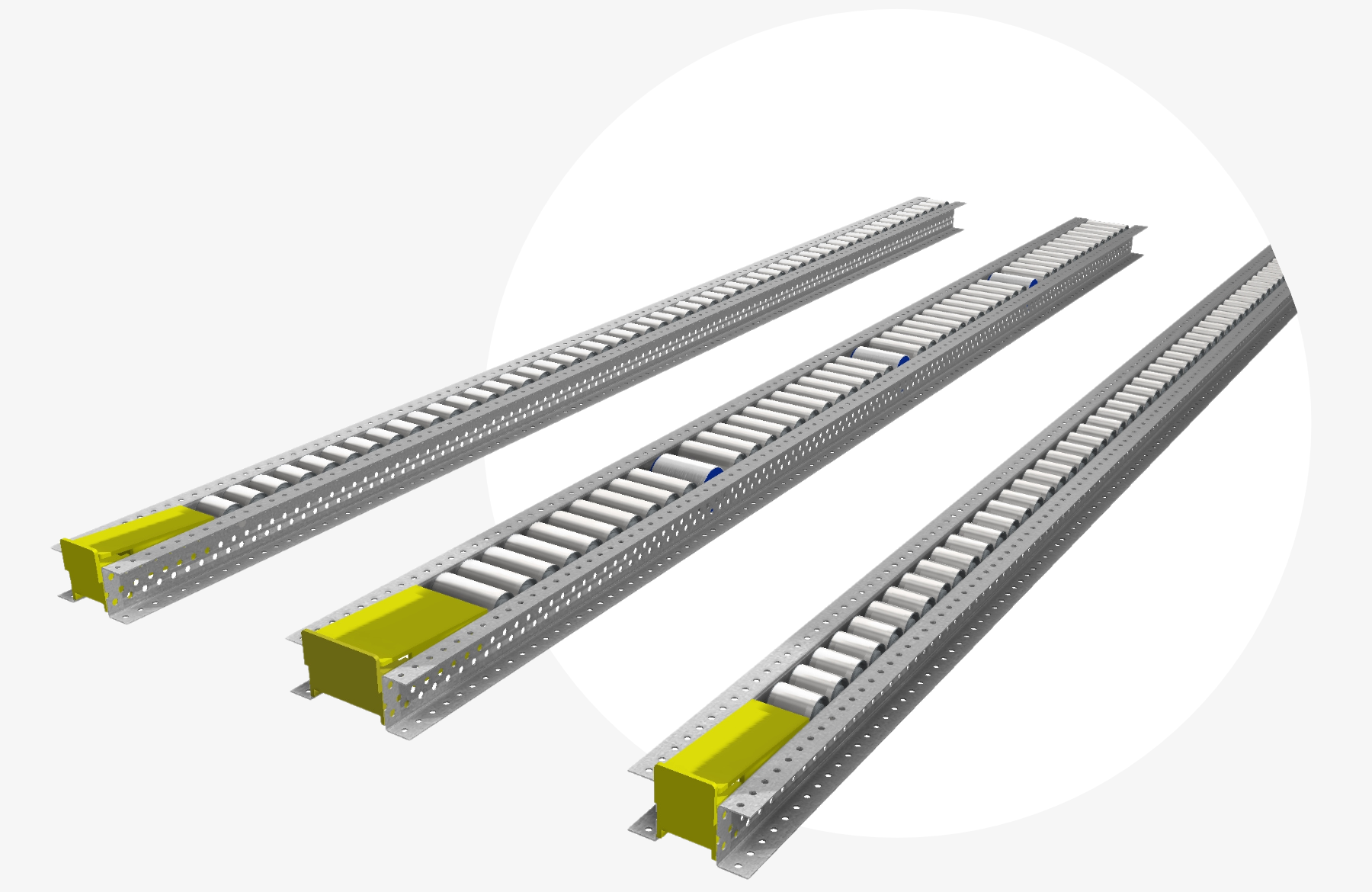

Intermediate Element

Full-Width Rollers

Independent of the material handling equipment.

The intermediate element is normally 2 pallet locations long. The number of center elements in line determines the depth of the roller conveyor.

Triple Track System

Split Roller Design for all pallet sizes.

Pallet Flow solution with galvanized steel rollers and open steel profile. Compatible with all rack systems for optimized space usage.

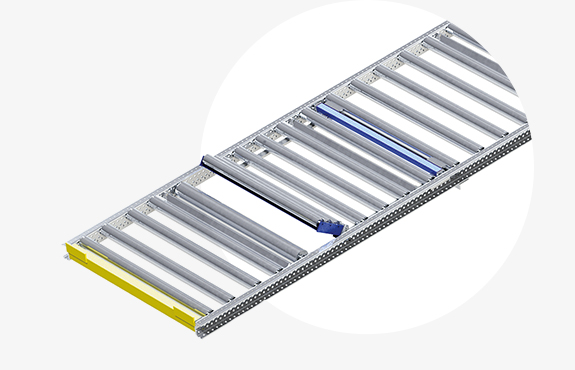

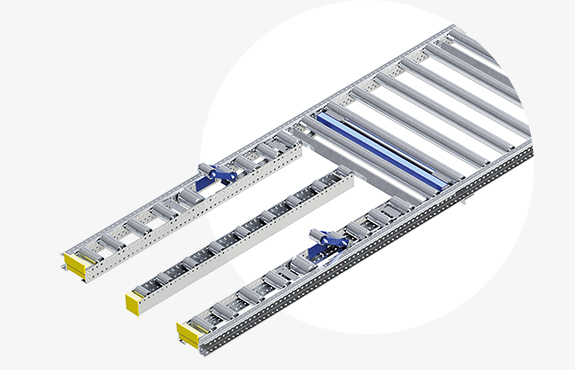

Unloading Elements

Full-Width Rollers

For material handling equipment with tilting mast.

The separating device creates space between the pallet to be removed and the ones stored behind. With end stop to protect the rollers in daily use, marked with yellow signal color.

Split Rollers

For material handling equipment without mast inclination.

Depending on the type of pallet, the unloading element is divided into two or three parts. The pallet retainer separates the pallet to be removed from the following ones. With end stop to protect the rollers in daily use, coated in yellow signal color.

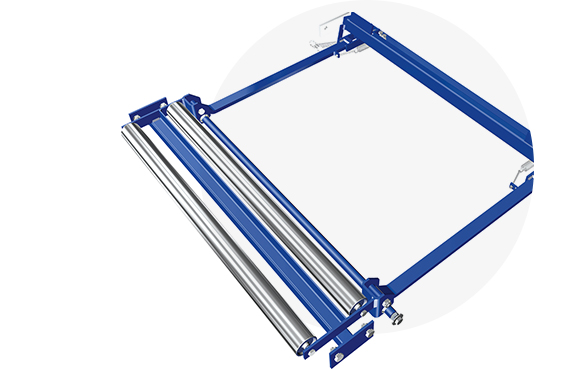

Floor Element

Optionally with additional reinforcements.

Optionally with additional reinforcements to avoid damage to the roller conveyor.

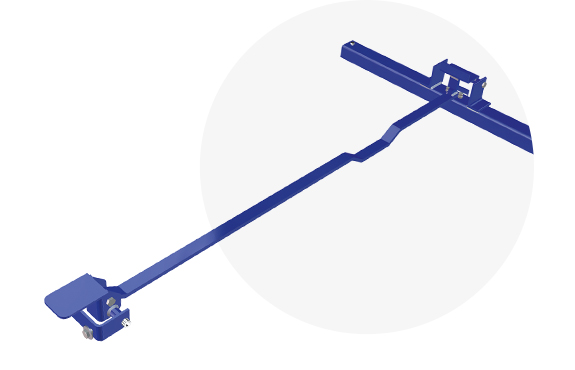

Cart Push Back

Cart System as an alternative to the Push-Back System with Rollers

For optimized LIFO crossway transport

Efficient handling, optimized safety and zero energy consumption. The Euroroll Cart Push-Back systems for storing up to 6 pallets deep. Compatible with all racking systems and can be used for almost all pallet types and steel racks. With up to 1,300 kg load per pallet space, the cart systems offer high storage capacity and up to 30% space savings compared to conventional racking.

✓ Suitable for almost all pallet types. Whether Euro pallets, CHEP pallets, GMA and many other Asian and Australian pallets.

✓ No accumulation pressure during removal, as the pallets do not touch each other during storage.

✓ Pre-assembled delivery of the carts and easy installation in existing racking.

✓ Robust, powder-coated rails and push-back carts, for tough everyday warehouse work.

Enhance Functionality with Euroroll Pallet Flow Racking Accessories

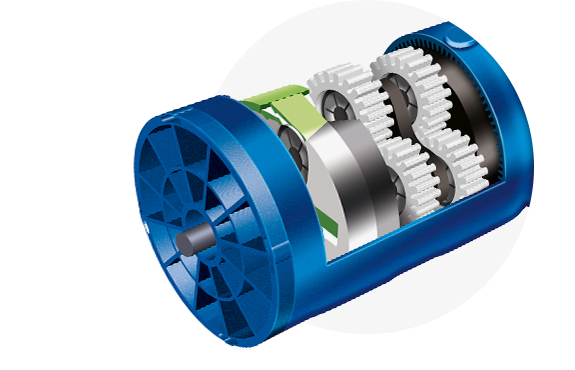

Fine-Tune Pallet Movement with Euroroll’s Speed Controller

Rubberized, knurled and standard. Brake rollers for every need. We advise you which brake roller is optimal for your needs.

Ensure Safe and Efficient Pallet Separation with Euroroll’s Separators

For fast and safe removal. The separating device is at the unload end and separates the pallet to be removed from the pallets behind.

Customize Your System with Additional Euroroll Accessories

Important accessories for your system. We advise you, individually tailored to your needs.

New Whitepaper: Pallet Flow vs. Pallet Shuttle

Efficient solutions for high-density pallet storage

The Fraunhofer Institute, in collaboration with Euroroll, has published a whitepaper comparing the two systems, Pallet Flow and Pallet Shuttle. You can download the whitepaper for free.