euroroll is proud to present some of the previous projects designed and built according to customer requirements. Particularly noteworthy are the unique solutions developed for each customer. euroroll guarantees the best possible solution for each customer, relying not only on the standard range but also on special solutions and custom-made products.

Automobile

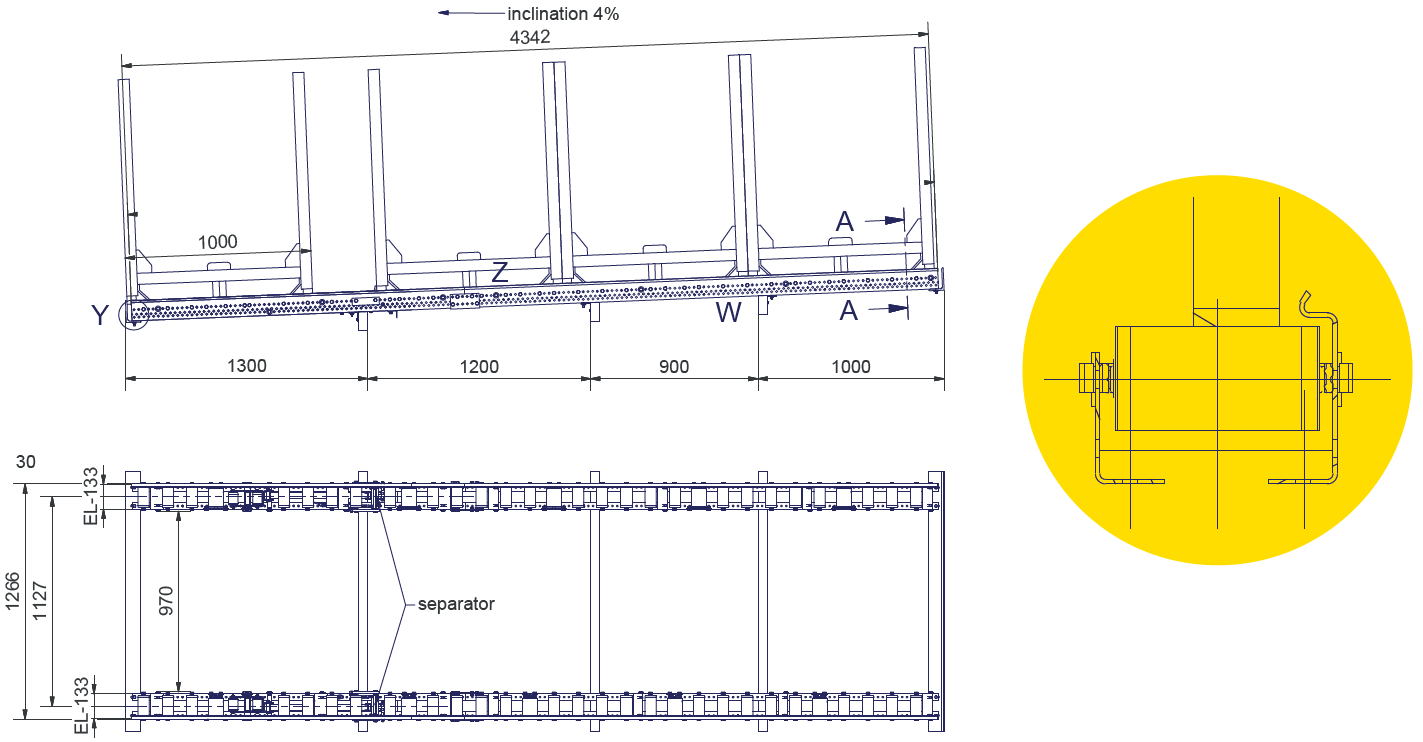

A completely new engine plant with state-of-the-art storage facilities and several blocks of flow racks were provided for this company in the automotive industry. A special solution was developed for the typical industrial automotive containers and steel frames, which includes a side profile with integrated side guide. In addition, the double separator with extra high holding stop keeps the first pallet free from any line pressure from the following pallets.

Commerce

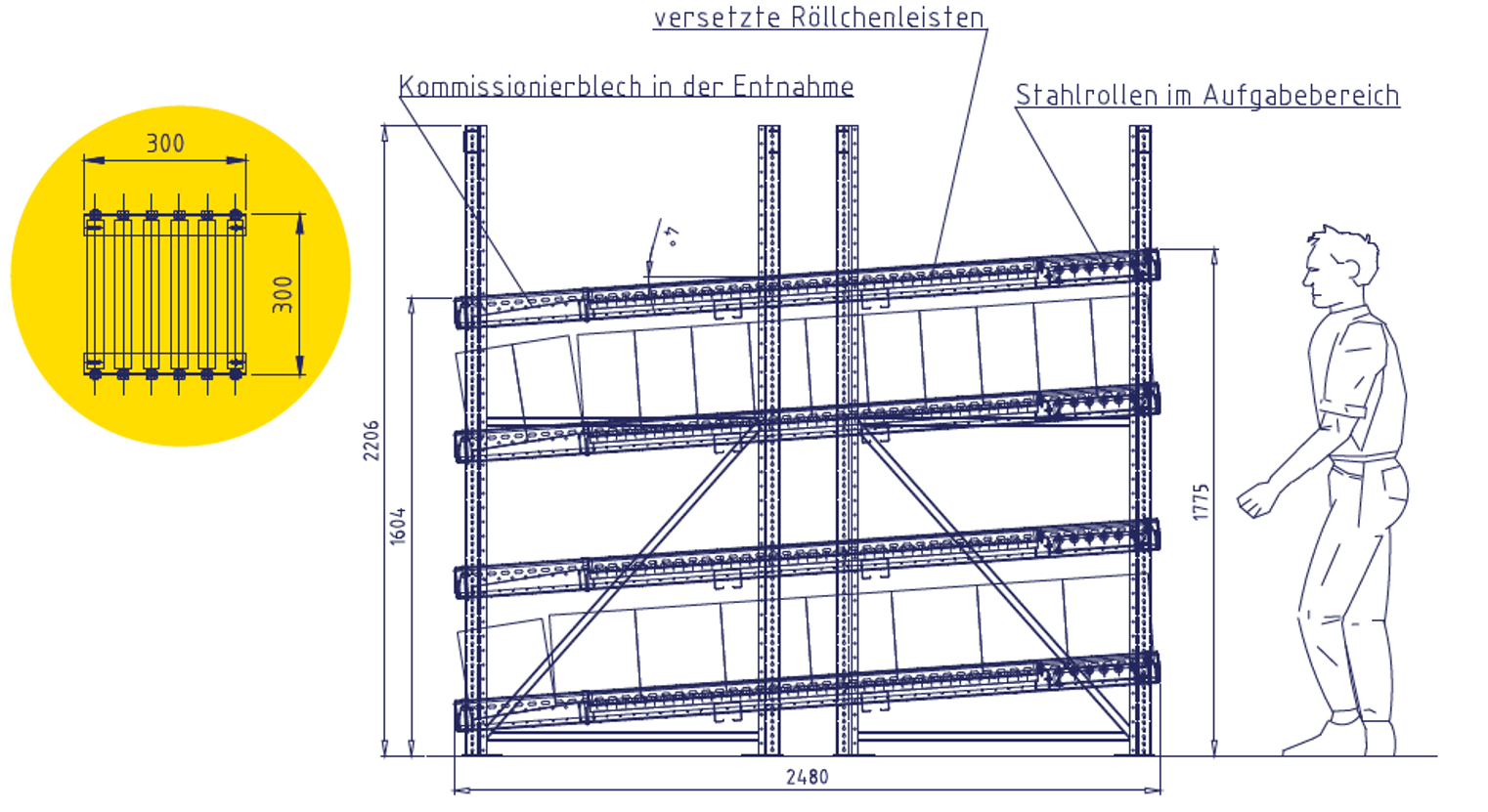

With the staggered arrangement of the wheel rails, Euroroll has found a solution to reliably transport crates with different irregular honeycomb structures to the picking station. On the unloading side, a tilted picking tray brakes the crates and presents them ergonomically so that they can be removed easily. The profiles of the Carton Flow, which work according to the FIFO principle, are made of galvanised steel and form an extremely robust construction.

Consumer Goods

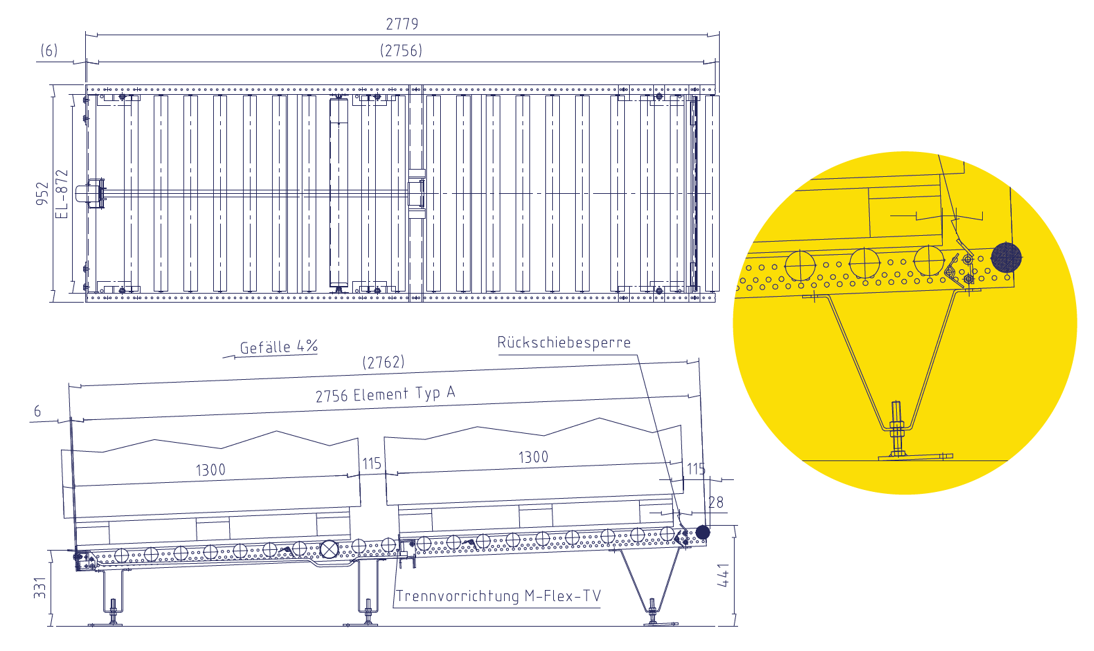

Euroroll has designed a semi-automated storage solution for one of Germany’s largest confectionery groups: a combination of gravity roller conveyors, driven rollers and automated loading by transfer car. The long, gravity-driven lanes are intended as intermediate storage (buffer solution).

The shuttle car loads them automatically with pallets. A separation device is installed at the end of the lane so that the operator can remove a pallet without line pressure. The tracks are suitable for operation with hand pallet trucks. The weight range of the pallets can vary between 80 and 1000 kg. A transfer trolley automatically fills the picking lanes.

Logistics

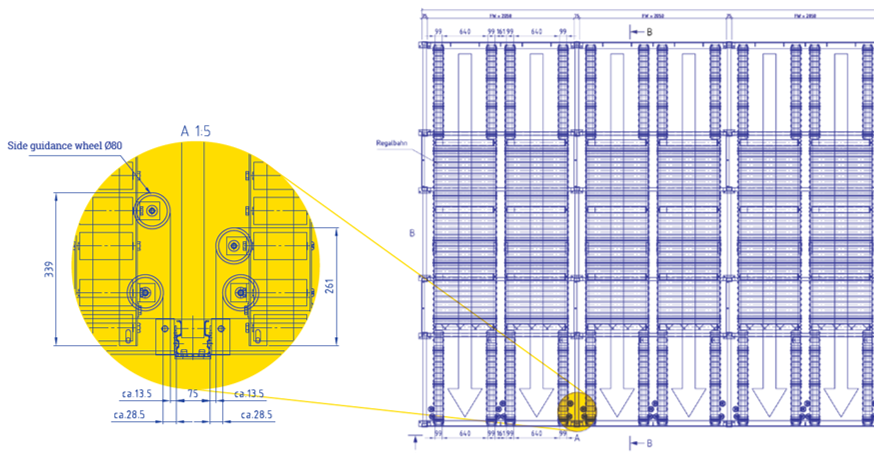

For this company, Euroroll was also able to use gravity roller conveyors with AGVs. The loading and unloading of the pallets is automated. This system can be loaded not only with standard Euro pallets, but also with special pallets, steel racks and plastic pallets. The configuration of the roller conveyors was done in close cooperation with the AGV manufacturer to ensure smooth and reliable operation. The integration of a sprinkler system and a full enclosure with fire protection cladding was also integrated.

Pharma

Two systems – together and not against each other!

For this company in the pharmaceutical industry, the advantages of two systems are used. The combination of gravity roller conveyors on the ground floor and a radio shuttle on the higher levels contributes to optimal order picking. The two systems complement each other perfectly and are supported by the Euroroll brake roller type EBT2S, which gently controls the transverse transport of the pallets and maintains the maximum discharge speed of 0.25 m/s. In addition, the “Flex TV” separating device, which has been specially modified for cross transport, enables the first pallet to be unloaded without line pressure and ensures fast and safe order picking. With the solution used, the unloading element of the roller conveyor can be raised by means of a gas strut. This facilitates cleaning of the floor underneath.