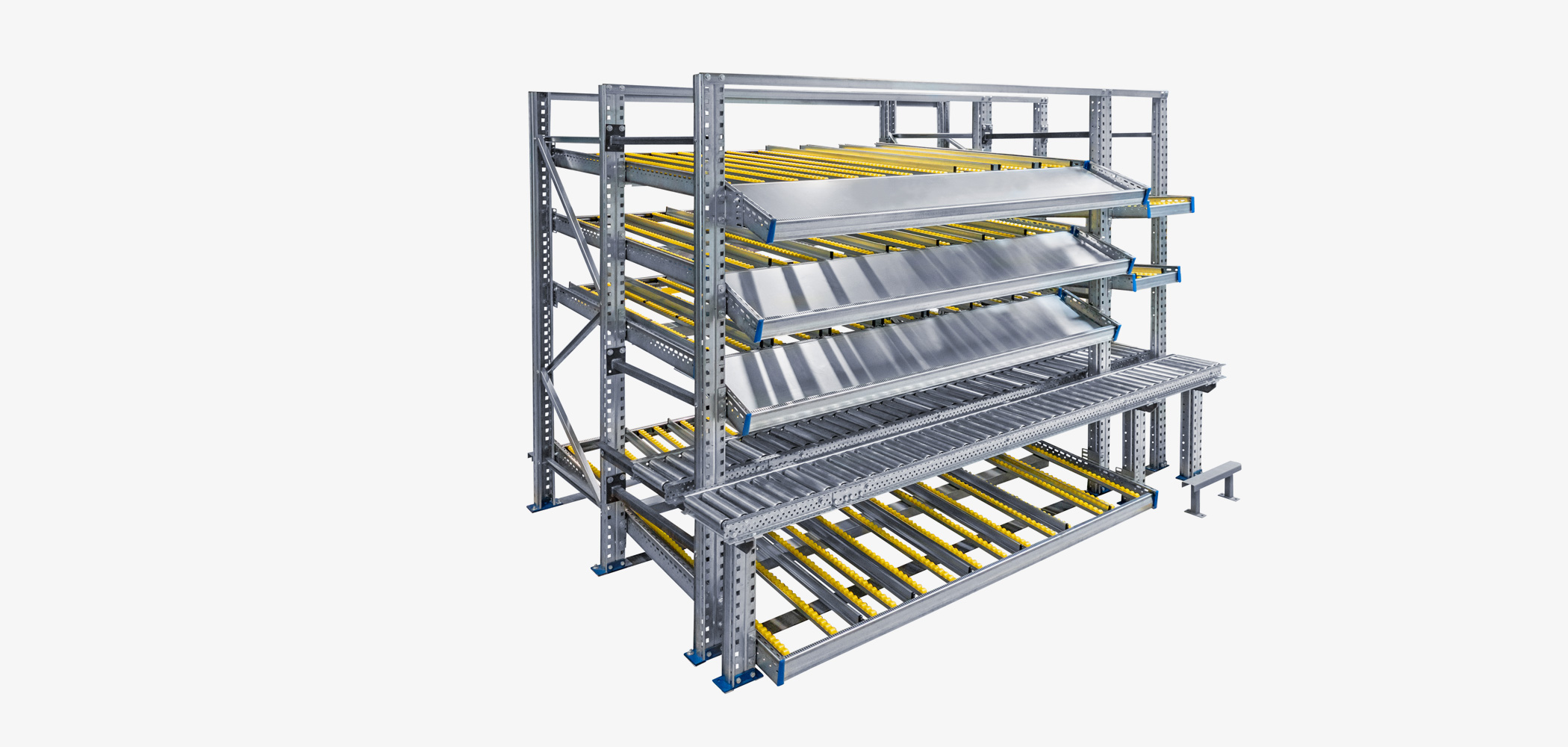

Less space required, increased work performance with more job satisfaction and thus higher productivity: these are, in brief, some of the most important advantages of Euroroll continuous picking systems, where gravity transports your goods in the warehouse from the infeed to the picking area on continuous frames with roller tracks.

At the heart of Euroroll’s continuous picking systems are flow frames with integrated roller tracks, which ensure that the goods move safely and in a controlled manner from the infeed along a gradient to the picking area. Our robust flow frames are available in numerous variations.

At Euroroll, we determine your requirements together with you. If the system requires it or if you wish, our test and development department will be happy to carry out test runs.

Advantages

✓ With Carton Live Storages, the aisles between the individual shelves are eliminated. The goods are loaded on one side and picked on the other. With the help of gravity, the goods move from the infeed to the picking area in a controlled manner. This saves up to 30 % storage space.

✓ Energy costs for transporting the goods from the infeed to the picking area are eliminated – gravity does it for you and you save cash.

✓ Feeding and picking is done in separate areas. Your operators do not get in each other’s way.

✓ Productivity in the warehouse increases. The working distances for your employees are shortened so that they can pick larger quantities of goods in the same amount of time. The automatic replenishment of goods also increases productivity.

✓ The shelf fronts of the Carton Live Storage can be adapted to the goods to be picked. Among other things, picking plates, steps for comfortable working and pick-to-light bars facilitate the work of your employees.

✓ Since superfluous working distances are eliminated and the Carton Live Storage can be ergonomically adapted, the satisfaction of your employees also increases. All this contributes to keeping them healthy and increasing their work performance.

✓ The gravity-driven conveyor technology of the Euroroll systems is low-wear, designed for continuous use and highly efficient. Individual parts can be replaced quickly if necessary (usually during ongoing operation).

Solutions

Euroroll Standard

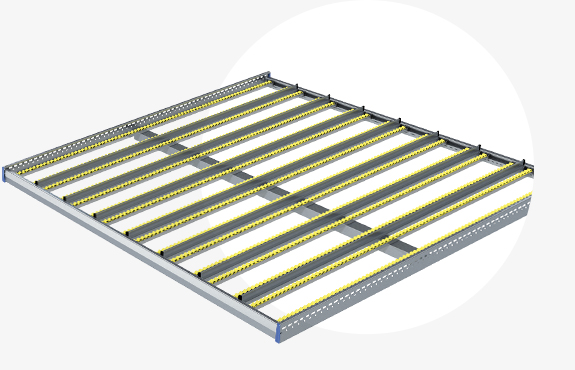

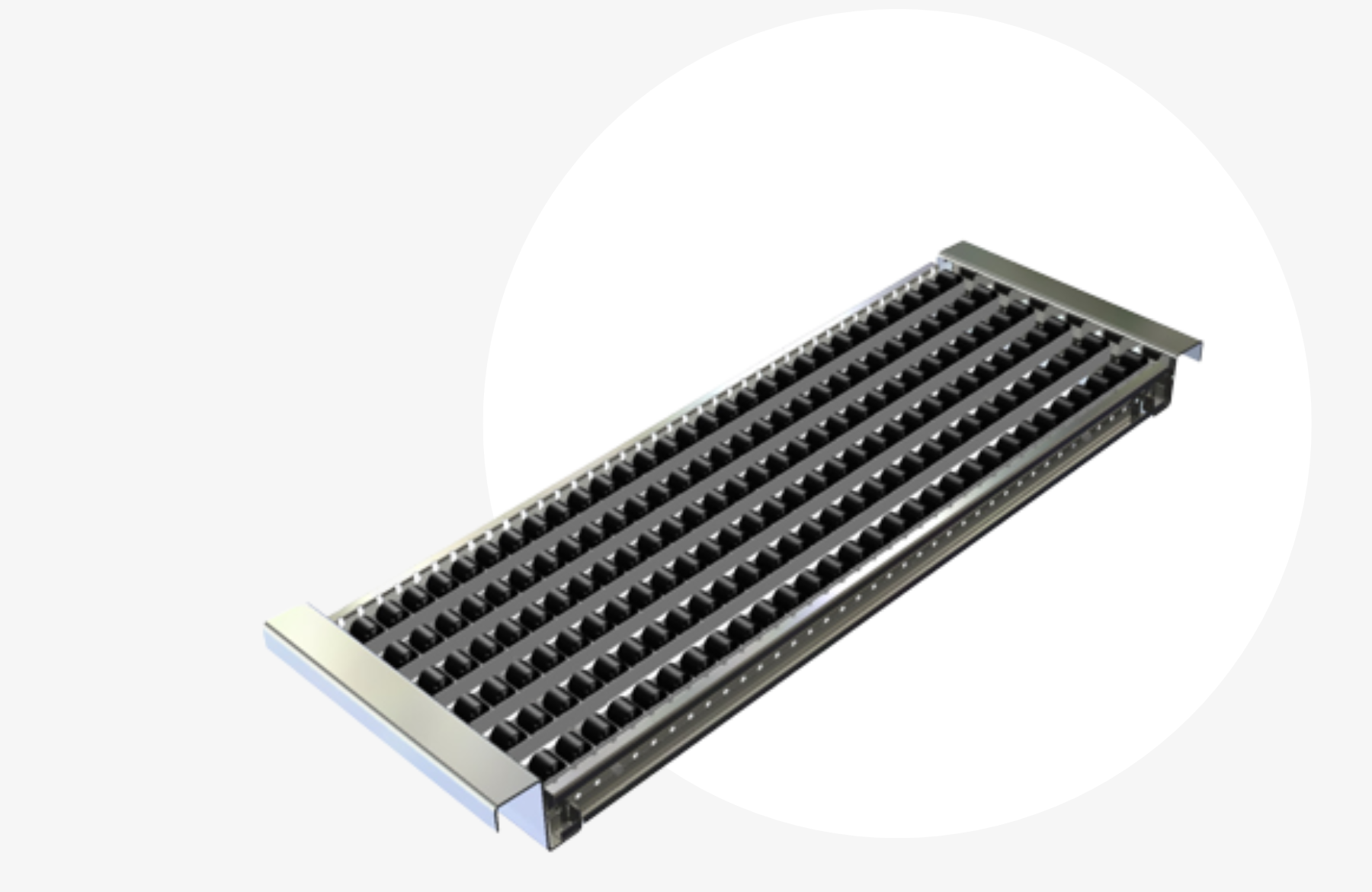

Carton Flow Bed

Consisting of loading, unloading and side profiles, crossbeams as well as roller tracks and guide rails.

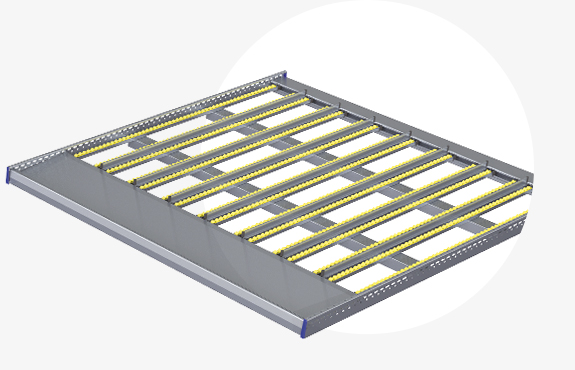

With picking tray

Facilitating the removal of the goods. Picking from totes or cartons is possible. Standard available in 300 mm, 400 mm and 600 mm depth and and with 5°, 10° and 15° tilt.

Hanger Style

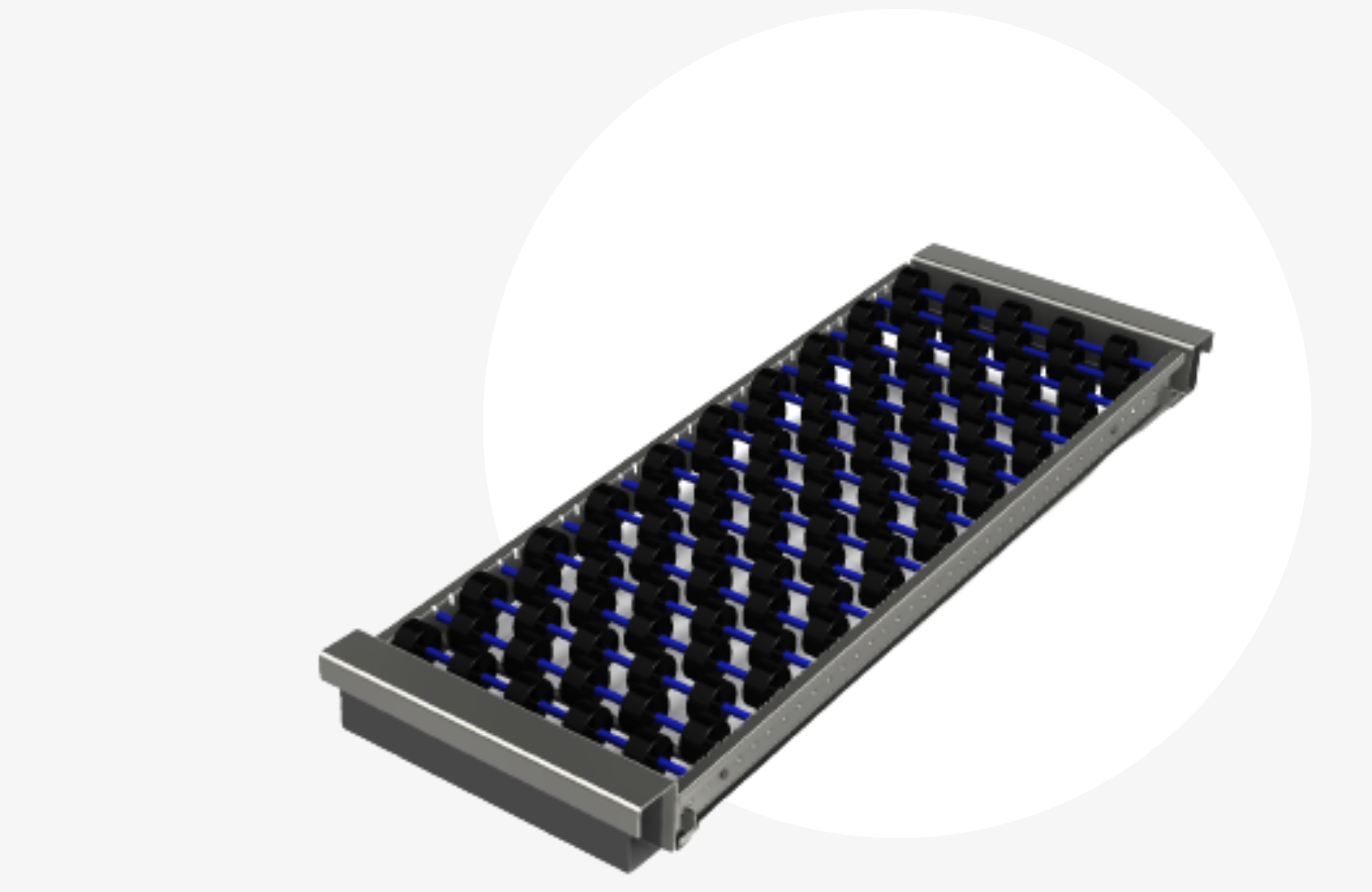

WheelFlow

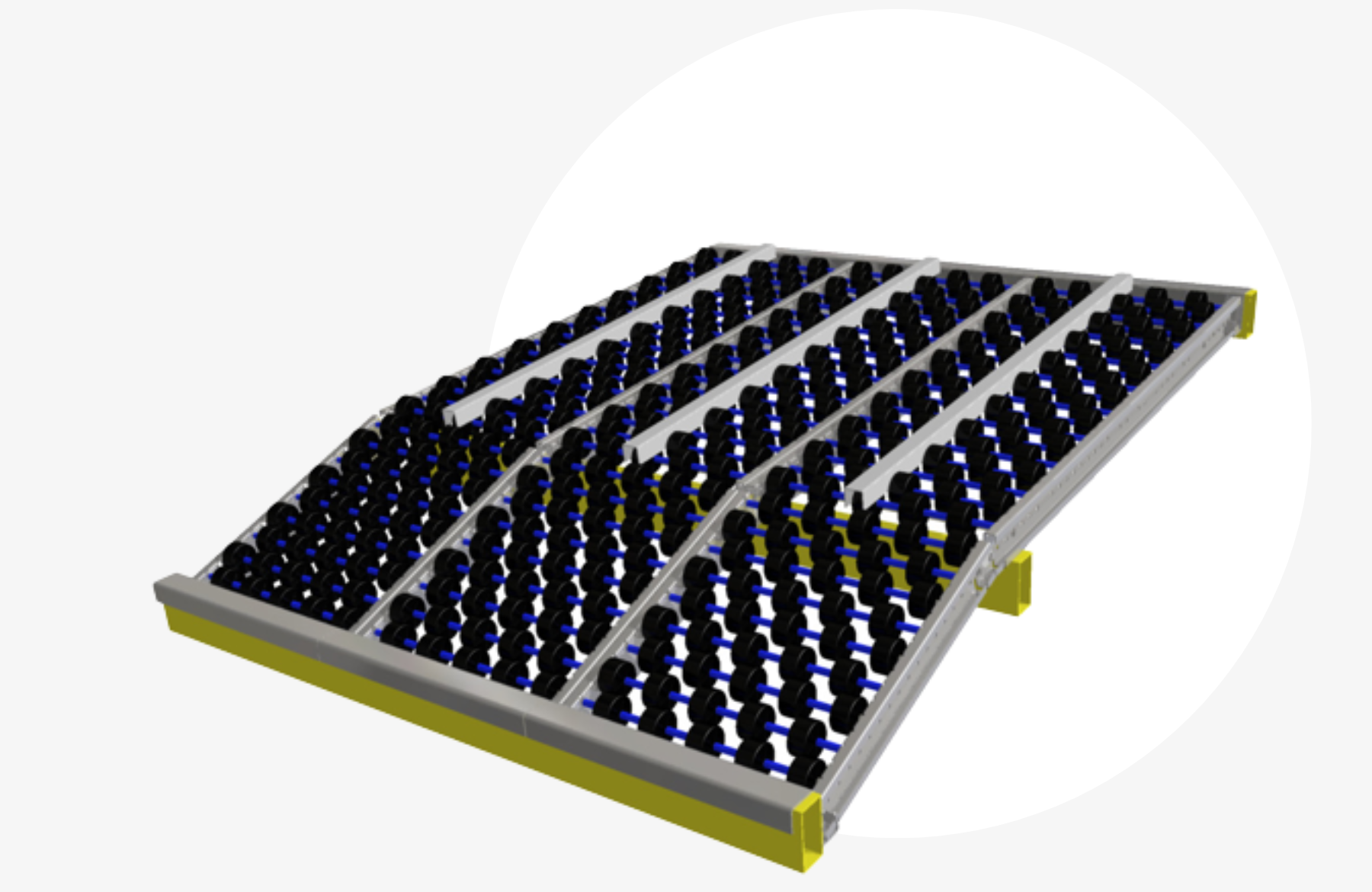

WheelFlow is our innovative solution for carton flow, regardless of your inventory size or shape. Easy installation in your new or existing rack to create the ultimate order picking environment. We offer all options for mounting: Hang it on the beam, mount it on step beams, or customize it to fit your beam.

TrackFlow

Euroroll’s exclusive Carton Flow Solution. Our roller tracks are designed for easy attachment to beams. You can customize them to your specific needs, whether it’s in terms of length, width, or the number and color of roller tracks. Create versatile storage space with staggered tracks to boost functionality. We also offer an anti-static version and snap-in full-length dividers for optimized picking.

RollerFlow

Euroroll RollerFlow drops into existing structures and creates flexible storage space for medium heavy loads. Our galvanized, durable rollers provide reliable flow for all kinds of kegs, boxes and totes. Maximize your floor space and improve productivity. Secure the fit with custom mounting brackets.

With Knuckle

All our Flow Solutions are also available with knuckled trays. Our tilt tray is a beneficial accessory that can be installed on the pick side of the carton flow system to enhance order picking rates and accuracy. Cartons or totes are loaded into the system on the loading side and flow on slightly inclined wheel (or roller) beds toward the unloading end or pick face. More ergonomically comfortable position picking.

Components

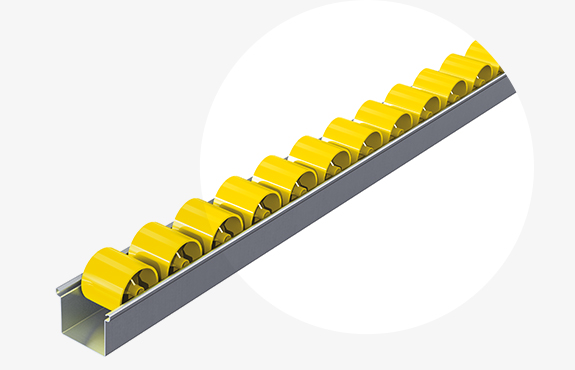

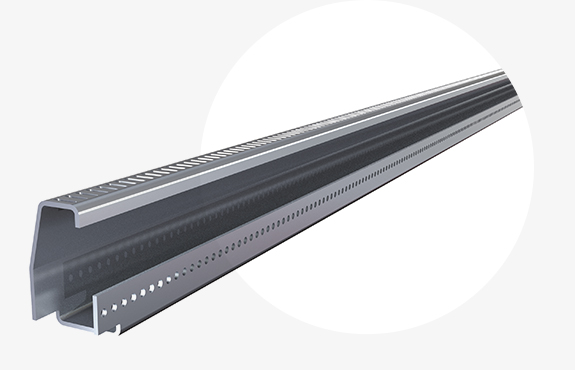

Roller tracks

Particularly resilient and low-wear. Many different designs, depending on the type of goods and load.

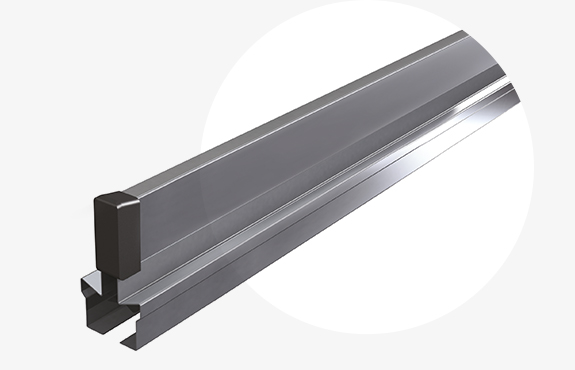

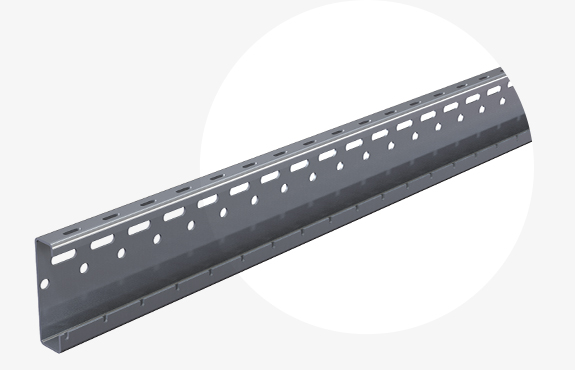

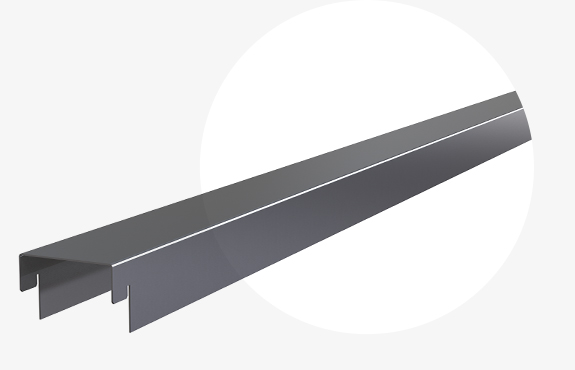

Guide rails – AFÜ

Keep your goods on track – from loading to picking – made of galvanised sheet steel, powder-coated and available in various lengths.

Rail connector

Fix the roller tracks and guide rails to the ends of the continuous frame.

Locking Pin

Are responsible for the easy assembly of your system. Side profiles can be firmly connected to the feed and removal profiles with their help. However, they can also be unlocked just as easily if a conversion is to take place.

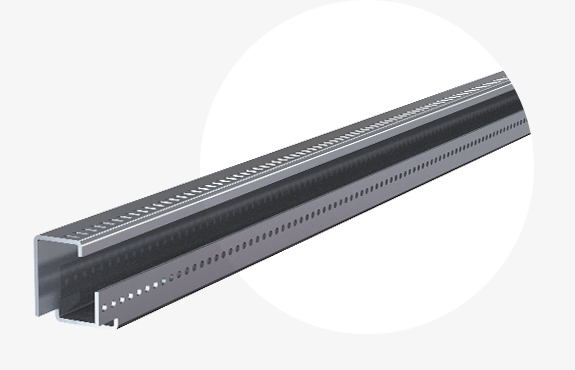

Loading profiles

These have a low overall height for ergonomic reasons and at the same time give the flow frame stability. For flow frames with a picking tray, an additional profile is used to hold the roller tracks and guide rails. In this way, the flow frame remains highly flexible.

Unloading profiles

Are reinforced to ensure the widest possible frame width even with heavy loads.

End bung

To be placed on the loading and unloading side. Ensure the safety of your employees.

Side profiles

Are connected without screws to crossbars as well as feed and removal profiles.

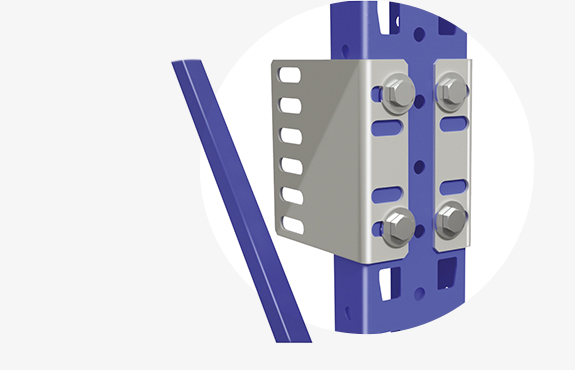

Adapter

A universal adapter is used to screw a Flow shelf to a racking. Adapters are regularly available for uprights from 50 mm to 75 mm or for uprights over 75 mm.

Crossbeams

Are mounted without bolts and increase the stability of the carton live frame. Additional beams increase its load-bearing capacity.

Accessories

Roller rails and tracks

Roller tracks can be used to move light goods in cardboard boxes, storage boxes, order-picking boxes or transport boxes. Depending on the design, roller tracks can be used as guide rails and installed in packaging machines. They also form the guides for drive belts.