Optimizing Your Warehouse: A Simple Guide to Pallet Flow and Pallet Shuttle Rack Systems

Optimizing Your Warehouse: A Simple Guide to Pallet Flow and Pallet Shuttle Rack Systems

Introduction

Efficient storage solutions are crucial for warehouse management. This guide simplifies the key points about two popular systems: Pallet Flow and Pallet Shuttle rack systems. These systems help maximize space and improve operations.

What Are Pallet Flow Systems?

Pallet Flow Systems use gravity to move pallets on inclined rollers from loading to unloading points. They consist of:

- Rack Structure: Supports the system.

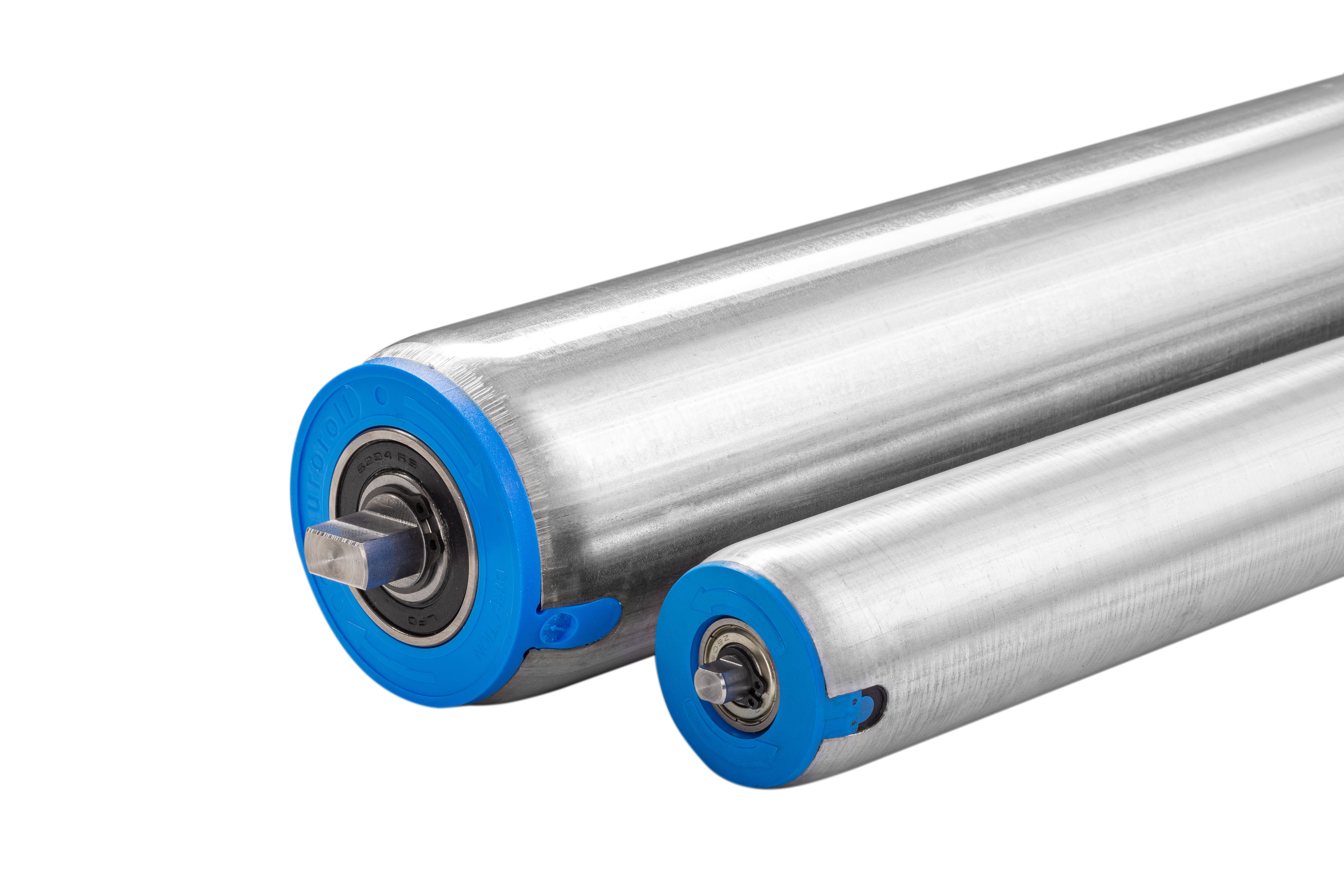

- Conveyor Rollers: Move pallets down a slope.

- Brake Rollers: Control the speed of the pallets.

- Centering Rails and Stops: Keep pallets aligned.

Pros:

- Fast Movement: Great for high turnover.

- Affordable: Lower cost than automated systems.

- Flexible Use: Works with both FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) methods.

Cons:

- Gravity Dependent: May not fit all layouts.

- Maintenance: Needs regular checks.

What Are Pallet Shuttle Systems?

Pallet Shuttle Systems use automated shuttles to move pallets within storage channels. They include:

- Rack Structure: Designed for shuttle movement.

- Shuttle Vehicles: Transport pallets to the right spot.

- Guiding Rails: Keep shuttles on track.

Pros:

- High Density: Maximizes space usage.

- Automated Options: Can work with AGVs for more automation.

- Precise Retrieval: Accurate pallet placement.

Cons:

- Higher Costs: More expensive to install and maintain.

- Complex Operation: Needs advanced control systems and training.

Choosing the Right System

Consider These Factors:

Goods Condition: Shuttles handle sensitive goods better.

Space: Pallet Flow needs less width.

Integration: Flow systems are simpler but less flexible.

Automation: Shuttles offer more automation.

Compare Costs and Efficiency:

Cost: Pallet Flow is cheaper upfront.

Throughput: Shuttles can handle more pallets at once.

Maintenance: Flow systems are easier to maintain.

Conclusion

Both systems have their advantages. Choose Pallet Flow for cost-effective simplicity and Pallet Shuttle for advanced automation and higher density. The right choice will boost your warehouse efficiency and productivity.

For more detailed information, read the full white paper by EuroRoll: https://www.euroroll.de/wp-content/uploads/2024/01/ENG_Whitepaper-Pallet_Flow_and_Pallet_Shuttle_Rack_Systems.pdf